|

October 2019,

MARIETTA, GA ~

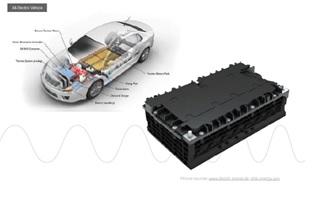

Gantner Instruments specializes in data acquisition of electrical, thermal and mechanical measurements in test automation. The Q.series product range offers best performance and high isolation for the evaluation of batteries for electrical drives, no matter if you are dealing with hybrids, plug-ins or all-electricals. In fact, the Gantner solution was selected by a German battery manufacturer for testing on its new 48 Volt battery management system.

Why is this so important? The new 48 Volt battery for hybrids is saving fuel and producing far less CO2 emissions. How? Every time a car is braking, it loses energy. With the help of a so-called boost recuperation system (BRS), the energy can now be stored and used later when the car accelerates again. Thanks to the battery’s housing made of plastic instead of metal and no need for active cooling, the new 48 Volt hybrid battery is less expensive. It is standardized for easy integration into new vehicle models and will make the hybrid system more affordable for a broader market. And Gantner is right in the forefront of this exciting and expanding technology! Why is this so important? The new 48 Volt battery for hybrids is saving fuel and producing far less CO2 emissions. How? Every time a car is braking, it loses energy. With the help of a so-called boost recuperation system (BRS), the energy can now be stored and used later when the car accelerates again. Thanks to the battery’s housing made of plastic instead of metal and no need for active cooling, the new 48 Volt hybrid battery is less expensive. It is standardized for easy integration into new vehicle models and will make the hybrid system more affordable for a broader market. And Gantner is right in the forefront of this exciting and expanding technology!

The testing of the 48V Battery Management System involved 15 DAQ-systems with a total of up to 60 input channels each, measuring voltage and temperature on the lithium-ion cells with an interface to the clients DAQ software using Modbus, Ethernet and EtherCAT.

Temperature profiles and thermo-mechanical load conditions were simulated to prove the suitability of the new materials and components. Voltage and current were measured and wide range temperature measurements were performed as thermal cycles.

The ability to freely mix and distribute the DAQ measurement modules made the Q.bloxx series the preferred choice. It offers the highest overall system adaptability and expandability and in this particular application, about 700 modules got into action (A101, A104, A105, A107, A124, A127 and A128). All GI Q.bloxx series modules share the following features:

-

RS485 fieldbus interface up to 24 Mbps RS485 fieldbus interface up to 24 Mbps

-

LocalBus up to 112 kbps

-

Connectable to any Q.controller, e.g. Q.station

-

Electromagnetic Compatibility according to EN61000-4 and EN55011

-

Power supply 10 … 30 VDC

-

DIN rail mounting (EN60715)

The TC, Pt100/Pt1000 and NTC sensors contributed to the high precision of the temperature measurements and last but not least the permanent galvanic isolation of the channels (1200 VDC).

As controller, the GI Q.station 101 was perfectly equipped for the job with it’s:

-

High data rates of up to 100 kHz at 8 channels (2 each UART line), 10 kHz at 128 channels High data rates of up to 100 kHz at 8 channels (2 each UART line), 10 kHz at 128 channels

-

Connectability with 64 Q.bloxx modules

-

Ethernet interface for configuration and data output (1 Gig-E, TCP/IP, UDP, up to 16 MB/s Modbus TCP/IP, ASCII, High Speed Port Web server, web client and e-mail)

-

Fieldbus interface (EtherCAT-Slave, 1024 variables read and write at 10 kHz, 1xCAN, 2 x USB 2.0, 4 MB/s)

-

Synchronization and time stamp of measurement values (IRIG 2 based master slave principle on RS485 standard system synchronization ±1 ìs applicable)

-

Data buffer memory dyn. 500 MByte, stat. 4 GByte (expandable over USB, up to 1000000 measurements/s) and SD card)

-

8 digital inputs / 4 digital outputs (direct connection of encoder for fast angle measurement frequency, PWM and countermeasures, state signals)

-

Also used, the controllers Q.pac EC and Q.gate IP/DP

For additional information on the Q.series, high isolation DAQ modules

click here For additional information on the Q.series, high isolation DAQ modules

click here

To

request additional information please contact FLW Southeast at:

sales@flwse.com To

request additional information please contact FLW Southeast at:

sales@flwse.com

|

|

|