|

MARIETTA, GA – 04/2010

Open connectivity for a fully integrated solution

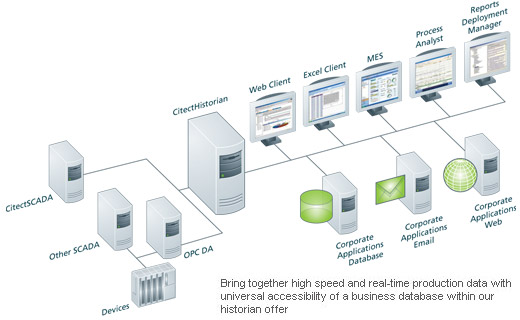

CitectHistorian is the industry's ‘most open' historian designed to help you improve plant operation and management. By utilising these industry standard protocols, the integrated decision analysis solution will help bridge the gap between production and business systems.

OPC HDA Server is offered as standard protocol for CitectHistorian, closing the gap between systems by freely connecting to manufacturing execution systems (MES), such as Schneider Electric's Ampla solution. This connectivity can help deliver a fully integrated solution, enabling you to benefit from the latest product and services innovations from a single provider.

OPC DA client is an industry standard protocol which CitectHistorian offers as standard, extending its open connectivity to any third-party SCADA system and providing you with a complete picture of your plant data source.

CitectHistorian utilises 100% Microsoft SQL Server 2005 as its embedded historical data store. This industry standard bridges the gap between plant and business systems through a common server which is well-known and trusted amongst IT professionals. Additionally, its open, industry-standard technology and trusted security integrate effortlessly into your business and, with MS Office, in a way that lowers your Total Cost of Ownership. The simple roll-out of familiar MS SQL technology results in reduced installation costs and little or no training time and expense.

This open architecture allows you to extract maximum value from the huge volumes of process data and realise benefits such as:

-

Reduction in project engineering costs and implementation times, with an improved interface that enhances visibility

-

Reduction in maintenance costs with one standardised connectivity platform, replacing multiple project solutions

-

Reduction of the load on systems, enhancing asset optimisation

-

Achievement of industry standards compliance via defined best practise implementation processes

-

Fully integrated systems, with plant and corporate data more readily combined and available, enabling timely business decisions

-

Freedom to access to manufacturing system data through a single point to business applications

-

Secure, long-term storage of data in a standardised format

Who will benefit from this open connectivity?

-

Customers seeking a fully product-based solution - rather than a project solution that becomes orphaned over time - with all the ongoing support capabilities will benefit from the historian's open connectivity.

-

Customers seeking a single supplier to provide a total, integrated SCADA and MES solution can benefit from this open technology.

-

Customers seeking an industry standard solution to reduce costs of interoperability with their existing (or corporate mandated) systems.

Benefits for corporate and plant personnel

-

Business managers can access meaningful, rolled-up production system information from the plant floor in the familiar reporting format they use for their financial or other business reports. This information can help them make strategic decisions for operational performance optimisation.

-

Plant managers can drill down into information on prohibitors to production efficiency or spurious alarms.

-

Corporate and plant personnel can

quickly and easily create and access meaningful reports in a

familiar format, through file share, web portal, MS Excel, MS

Reporting Services or through ad hoc and user-defined formats, to

create a single view of operations.

-

Maximise asset utilisation and improve operator effectiveness by identifying areas for process efficiency improvements.

-

Remove the headache of producing reports for customers and regulators.

-

Change the volume of data at no extra cost.

Turning your data into meaningful information with Process Analyst

Our intuitive visualisation tool, Process Analyst, allows you to easily view plant processes with embedded trend and alarm data all on a single, integrated display. This sophisticated visualisation analysis tool is now available with historian data. This means you can analyse the cause of process upsets not only from the SCADA level but also from the historian level.

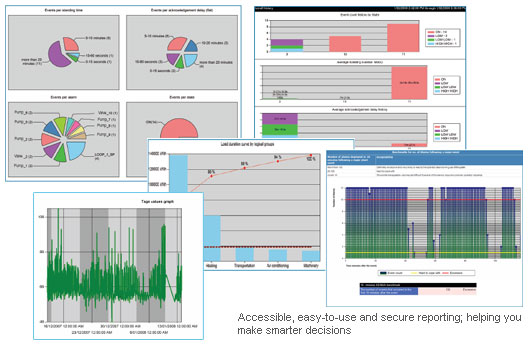

Powerful Reporting

With CitectHistorian, you can now produce a range of reports using a convenient built-in historian in the familiar, open Microsoft user interface which only an embedded MS SQL server makes possible. The combination of the powerful reporting tool and Process Analyst makes it easier for you to make sense of the huge volumes of generated data.

Reports Deployment Manager delivers a standard set of pre-configured reports and its out-of-the-box sample reports contain a collection of reports designed to meet the needs of specific industries or skill levels, simplifying alarm and tag reporting. Alternatively, you can opt to customise these reports to suit your individual requirements. We have introduced the concept of hierarchical tag grouping. This concept enables you to organise your data according to your business reporting requirements.

Alarm Rationalisation and Alarm Management Reports (EEMUA 191 guidelines)

CitectHistorian provides pre-configured alarm rationalisation reports based on the EEMUA (Engineering Equipment & Materials Users Association) 191 alarm management guidelines. Alarm management is a set of procedures, practices, tools and systems that jointly ensure a plant's alarm system is effective throughout the life of the plant.

With the alarm management reports, operators are provided with more meaningful and actionable information. The reports are designed to improve the average and maximum number of alarms per hour, operator response time, usability and relevance. As a result, there are fewer incidents and less downtime.

Comprehensive energy reports for a "Green" environment

Energy can be the largest component of a manufacturer's cost structure and gone are the days of abundant and relatively cheap energy supply. The age-old credo of process control is, "You can't control what you can't measure." This certainly applies to the realm of energy management and this is where CitectHistorian can make a significant difference in your operations. CitectHistorian's Energy Reports help you perform a comprehensive energy assessment of your plant, to determine how much energy is being consumed and how much could potentially be saved.

|