|

MARIETTA, GA –

08/2010

-

Industry: Food & Beverage

-

Service: Flow Rate/Total

-

Fluid: High Fructose Corn Syrup (HFCS), Water,

Vinegar, Buttermilk, Egg Product and Mayonnaise

Overview

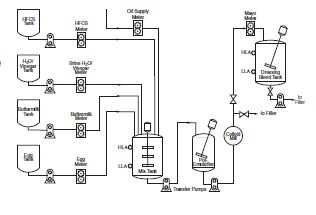

One of the critical factors affecting the quality of any food product is the proportion of the ingredients

added to it.When making salad dressings, for example, manufacturers frequently utilize batch

processes involving various ingredients, in different quantities, added to a mixing tank. This

process can include High Fructose Corn Syrup (HFCS), water, vinegar, buttermilk and egg product

to produce mayonnaise, and requires measuring the flow rate of the mayonnaise itself. For

mayonnaise, viscosity eliminates many flow meter technologies.

Situation

A large manufacturer of sauces and dressings located in the Southeastern U.S. sought to improve

the quality control of its products. The company previously employed manual batching, but wanted

to upgrade its operation to automated production processes. It required a single type of flow meter

to control the amount of mayonnaise added to salad dressings, as well as flow meters for each

ingredient used in the mayonnaise process.

Solution

The head of plant maintenance had successful results using Flow Technology’s Decathlon Series Positive Displacement (PD) flow

meters at his previous company, and viewed them as the best solution for producing salad dressing with excellent quality and

consistency.

Initially, the plant had three mayonnaise dispensing points to be

measured. The local FTI representative determined that three-inch

DC-F Sanitary Series PD flow meters could be employed to handle

the high-viscosity fluids at high flow rates with the lowest pressure

drop across the meter. The customer also used FTI’s Hall Effect

Sensor for a pulse output transmitted directly to the plant control

system for the batch control function. Initially, the plant had three mayonnaise dispensing points to be

measured. The local FTI representative determined that three-inch

DC-F Sanitary Series PD flow meters could be employed to handle

the high-viscosity fluids at high flow rates with the lowest pressure

drop across the meter. The customer also used FTI’s Hall Effect

Sensor for a pulse output transmitted directly to the plant control

system for the batch control function.

Thanks to the DC-F Series meters, the salad dressing manufacturer

had a successful transition from a manual batch operation to

an automated batching process. It subsequently ordered additional

meters to measure and batch HFCS, water, vinegar, buttermilk and

egg product used in making mayonnaise, as well as other dressings

and sauces.

System Description

For measuring and batching mayonnaise (at 5000 cP), the customer chose the DC30F-6113-5430000 PD meter along with the

IS160-01 Hall Effect sensor and 19-94506-01 sensor cable. For HFCS, buttermilk, soy oil, chilled water and vinegar (at 1 to 3000

cP), it used the DC20F-6113-5420000 PD meter. The DC15F-6113-5415000 PD flow meter, Hall Effect sensors and cables were

selected for measuring egg product (at 100 cP).

Technical Information

Flow Meters: DC30F-6113-5430000, DC20F-6113-5420000,

DC15F-6113-5415000

Electronics:IS160-01 Hall Effect Sensor, 19-94506-01 Cable

Flow Rate: 12-32 GPM

Fluids: High Fructose Corn Syrup (HFCS),Water, Vinegar, Buttermilk,

Egg Product and Mayonnaise

|