cialis 20 mg

acquistare cialis in contrassegno clickcheap abortion pill near me

buy abortion pill online cheap|

Siemens New radar level transmitter:

Thoroughly tested |

|

May 2016, MARIETTA, GA~ COMPARISON TEST | In a study lasting more than a year, experts from SABMiller compared the Sitrans LR250 HEA radar level transmitter prototype – commercially available since September 2014 – against similar systems from other manufacturers and subjected them to thorough testing. As a result, the new transmitter satisfies the stringent requirements of EHEDG aseptic and has been accepted as part of the SABMiller standard for radar level measurement for brewing internationally. TODAY’S BREWING INDUSTRY is characterized by a constantly growing range of varieties and bottle shapes as well as increasing cost pressure. This is leading to a growing need for hygienic, reliable and low-cost systems capable of measuring the precise content of pressurized tanks prior to filling, as well as of fermenting and storage tanks. Since this purpose was previously served mainly by ultrasonic sensors and direct contact measurements of differential pressure transmitters, Siemens developed an appropriate system based on the Sitrans LR250 radar level transmitter, which has been successful in a range of industries. “In view of the specific requirements of the brewing industry,” says project manager Robert Gray of Siemens PI Level and Weighing in Peterborough, Ontario, Canada, “we placed particular emphasis on how to hygienically insert the probe and the variety of process connections as we were refining our proven radar level transmitter. In addition, we considered it important that the new sensor was easy to maintain and also repair in a worst-case scenario.” And the results are quite impressive: Sitrans LR250 HEA (hygienic encapsulated antenna), introduced in late September 2014, is not only much cheaper than ultrasonic-based systems offering comparable performance, but is also designed to enable replacement of the sensor’s electronics without having to disrupt the process by depressurizing and taking the tank offline.

Comprehensive

comparative study The first test was started on the BBT tanks. SABMiller’s requirement for this test was that the transmitter had to perform throughout the process of filling and emptying the vessel and to indicate the correct volume that was measured against the incoming flow via a magflow. The transmitter also had to keep a stable reading on the rousing process and to ensure the reading stayed stable despite the foam that is generated during this process. Throughout the various stages, volume is the most important measurement, as any discrepancy would generate losses between the Brewing and Packaging departments. The same function was to be mimicked on the FPT tanks but on those it was a little more difficult due the product being continuously agitated (fruit-based alcoholic beverages). The Chamdor Brewery fitted BBT pressurized tanks and FPT beer-based drink tanks (FPT) with radar level transmitters from three manufacturers and tested them under practical operating conditions.

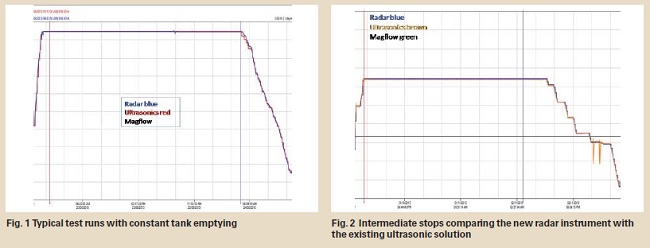

Figures 1 and 2 show typical test runs with tank emptying constantly or with intermediate stops comparing the new radar instrument with the existing ultrasonic solution. With an accuracy of 3 mm and a resolution of 1 mm the radar level transmitter can be used with tanks up to 20 m height as standard equipment. The process connections ranges from 2 to 8 inch with threads (DIN 11851, DIN 11864), clamps (ISO 2852, DIN 11864), flanges (ASME, DIN 11864) and Varivent.

Process Intelligence

Certified in accordance with

EHEDG Type EL Aseptic

Global standard for fill measurement The new radar level transmitter has the following benefits:

SABMiller’s assessment after more than

one year of test operations was positive:

“From our perspective, the criteria that we

were looking for have been satisfied. Sitrans

LR250 HEA has been adopted by SABMiller

as part of its Global Standard for fill measurement

– both for new projects and when

replacements are needed" |