|

Gantner Instruments Data Acquisition |

|

October 2018,

MARIETTA, GA ~

For Equipment in the Oil & Gas Industry

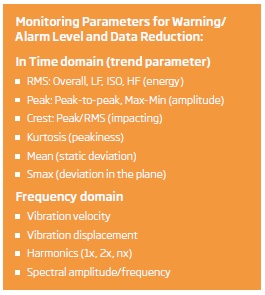

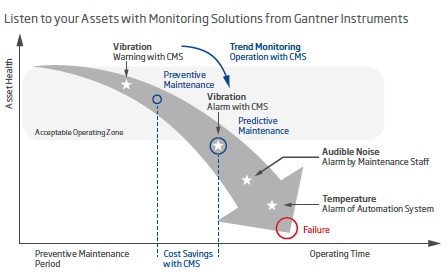

The monitoring solutions of Gantner Instruments provide your assets and equipment with “smart” capabilities enabling them to supply detailed status information about themselves. Machine-based operational data like vibration patterns are acquired by robust accelerometers. These sensors are also applicable at locations with high surface or ambient temperature up to 700°C. Uni- or triaxle sensors with IEPE or charge output are used depending on the monitoring task. The vibration signal is acquired with up to 100kHz per channel and can be processed in real time for trend monitoring or further analysis depending on the monitored asset. The system uses statistical parameters – in time or frequency domains – like RMS, peak-to-peak, crest or vibration velocity and displacement for trend monitoring. For plain bearings eddy current sensors / proximity probes are used to detect the exact location of the shaft in the bearing shell (Smax, orbit). These trend parameters reduce the amount of stored data and thresholds for alarm and warnings can be configured based on these parameters. The alarm and warning conditions are also used for triggered data storage of the raw data (up to 100kHz per channel). With its pre- and post-trigger, the system acquires the raw data before and after an event happened. For further data analysis all information is available. A large number of assets can be monitored with the web portal of Gantner Instruments. Based on a local or public cloud system the portal gives an overview of the asset health in terms ofcolor-coded symbols for the asset in general and all of its monitored components in detail. Dashboards with asset health status can be configured for the web portal. The same configuration can be used for setting up instrumentation from Gantner Instruments as well as with the visualization software GI.Bench. |

|

Vibration and Load Monitoring System For the petroleum industry, the reliable operation of pipelines, BOP and other equipment within acceptable vibration, temperature and mechanical load limits is essential for long-term operation as well as staff and plant safety. For all equipment, plant and assets, in the upstream midstream and downstream sectors, the remote monitoring and supervision of operating condition is essential for cost-effective maintenance strategies. For these applications also accelerometers, temperature sensors, load cells or displacement sensors and strain gauges are used to detect the load or overload conditions. Often, these types of assets are located in areas where no local network connection is available for data transmission and alarm announcement. Radio transmission, 4G/ LTE routers or satellite networks with a secured connection to the GI cloud server are used. With intelligent data reduction methods, e.g. Rainflow cycle counting for load conditions, a large number of decentralized assets can be monitored even with the smallest data transmission bandwidth. The cloud server can be installed locally in the corporate network without use of public cloud services to protect the data. Its powerful database enables evaluation of the complete fleet in just a few clicks. For temporary applications, a mobile version of the vibration and load monitoring system is available. This mobile system is used, for instance, in the acquisition of piping data – before and after exchanging pipes, valves or supports. In this case, the vibration pattern is measured and analyzed to detect eigenfrequencies or vibration velocity and displacement. This cost-optimized version offers the detailed data analysis of stability or vibration fatigue.  To learn more about Gantner Instruments Data Acquisition products, please click here. |