|

August 2019,

MARIETTA, GA ~ August 2019,

MARIETTA, GA ~

Ensuring work piece quality is the top priority in many sectors of industry. When the materials involved are difficult to machine, tool lifetimes can vary greatly – so continuous monitoring of tools is essential.

Tool monitoring during cutting processes delivers valuable insights into the actual process, providing the basis for reliable, productive and reproducible manufacturing processes.

Process monitoring ensures zero-defect production

-

Lower quality costs because deviations are detected at an early stage

-

Guaranteed process stability

-

Improved process efficiency thanks to optimized process parameters

-

Monitored production with full and partial automation in shift operation

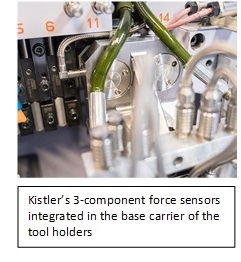

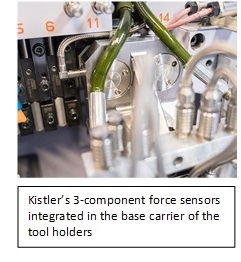

Kistler is the technology partner for tool manufacturers and machine tool builders Kistler is the technology partner for tool manufacturers and machine tool builders

-

Enhanced competitive edge thanks to unique machine features

-

Measurement technology connected directly to the machine control

-

Industry 4.0: real-time overview of tools and machines

-

Extremely durable structure for applications in harsh environments

-

Grinding, honing, polishing, and many others

DynoWare, Software for cutting force and test & measurement applications

Type 2825A DynoWare, Software for cutting force and test & measurement applications

Type 2825A

DynoWare, software for universal data acquisition with dynamometers and Kistler charge amplifiers. In combination with devices of the LabAmp Family and the DAQ-System Type 5697A DynoWare is a powerful software to acquire and display data.

1-/4-Channel Laboratory Charge Amplifier & Data Acquisition Type 5165A 1-/4-Channel Laboratory Charge Amplifier & Data Acquisition Type 5165A

Data Acquisition System for up to 28 channels Type 5697A

For more information on Kistler’s Cutting Force Measurement Solutions

click here For more information on Kistler’s Cutting Force Measurement Solutions

click here

|