September 2019,

MARIETTA, GA ~

Automobile manufacturing is highly automated and extensively uses laser sensors and laser scanners for Quality Assurance and regular Test and Measurement applications. Laser sensors are selected because they can quickly and accurately measure displacements or positions without touching the target. The non-contact measurement principles are ideal for measuring fast-moving parts, delicate parts that may scratch (such as paint or plastic) or hot parts such as engine components.

September 2019,

MARIETTA, GA ~

Automobile manufacturing is highly automated and extensively uses laser sensors and laser scanners for Quality Assurance and regular Test and Measurement applications. Laser sensors are selected because they can quickly and accurately measure displacements or positions without touching the target. The non-contact measurement principles are ideal for measuring fast-moving parts, delicate parts that may scratch (such as paint or plastic) or hot parts such as engine components.

Scanners are good for profiling surfaces to obtain complex shape profiles, panel gap widths, hole diameters, etc. These scanners bring not only the benefits of machine vision, but also the benefits of non-operator dependent measuring tools and techniques.

Designed for industrial and scientific applications, these sensors measure distances to within fractions of a micron at speeds near ten kilohertz. All models include digital and analog outputs.

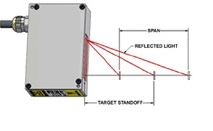

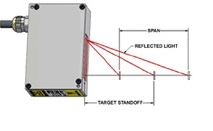

The AR700 is a triangulation sensor that measures distance by projecting a beam of laser light that creates a spot on a target surface. Reflected light from the surface is viewed from an angle by a CMOS detector array inside the AR700 sensor. The target’s distance is calculated from the image pixel data using the sensor’s microprocessor. The distance is transmitted through serial communications or analog outputs.

The AR700 is a triangulation sensor that measures distance by projecting a beam of laser light that creates a spot on a target surface. Reflected light from the surface is viewed from an angle by a CMOS detector array inside the AR700 sensor. The target’s distance is calculated from the image pixel data using the sensor’s microprocessor. The distance is transmitted through serial communications or analog outputs.

For more information on Acuity Laser Solutions

click here

For more information on Acuity Laser Solutions

click here

For a product recommendation or demonstration, please e-mail

sales@flwse.com

For a product recommendation or demonstration, please e-mail

sales@flwse.com

|

|