|

January 2020,

MARIETTA, GA ~

Continuous dissolved oxygen (DO) measurement is critical during fermentation and cell culture. But it does have its challenges. One of the main ones is signal noise. Air or oxygen bubbles from the sparger can accumulate on the DO sensor’s tip, creating a noise floor that is difficult to eliminate. January 2020,

MARIETTA, GA ~

Continuous dissolved oxygen (DO) measurement is critical during fermentation and cell culture. But it does have its challenges. One of the main ones is signal noise. Air or oxygen bubbles from the sparger can accumulate on the DO sensor’s tip, creating a noise floor that is difficult to eliminate.

Not anymore. The Mettler Toledo InPro 6860i HD Anti-Bubble Oxygen Sensor is mechanically modified with a hydrophilic surface with an angled tip design to prevent bubble accumulation providing a highly stable measurement signal.

Downloadable White Paper:

www.mt.com/oxygen-wp Downloadable White Paper:

www.mt.com/oxygen-wp

Eliminating Noisy O2 Measurements in Fermentation & Cell Culture

Stable reproducible yields Stable reproducible yields

Consistent batches and product quality is achieved by

reliable oxygen measurement. The proprietary hydrophilic

surface finish and tilted tip design prevent bubble

accumulation falsifying the results.

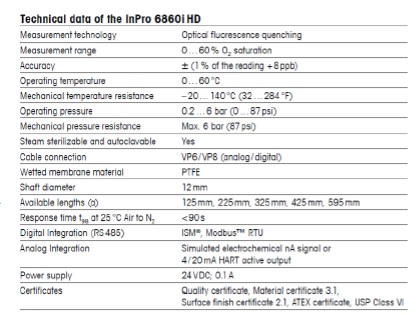

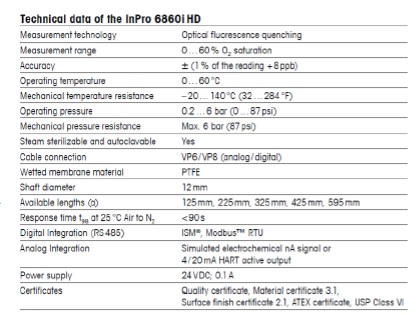

Hygienic and durable design

The PTFE layer on the OptoCap oxygen-sensing element

contributes to signal stability by preventing biofouling from

affecting measurements. The OptoCap has excellent

durability & withstands autoclaving and standard CIP / SIP

cycles.

Uncompromised reliability Uncompromised reliability

Pre-batch sensor

maintenance, thanks to

advanced diagnostics data,

ensures that the installed

sensor will operate reliably

throughout the batch.

Exceptional performance

Low handling time and

running costs due to reduced

calibration and maintenance

needs. This is achieved by an

electrolyte-free, one-piece

replacement part.

For more information,

www.mt.com/pro_pharma

For more information,

www.mt.com/pro_pharma

To request additional information

please contact FLW Southeast

sales@flwse.com To request additional information

please contact FLW Southeast

sales@flwse.com

|

|

|

Downloadable White Paper:

Downloadable White Paper:

Stable reproducible yields

Stable reproducible yields