|

AMETEK LAND - Understanding the Importance of 'HOT SPOT' Measurement in Non-Contact Temperature Measurement Applications

|

|

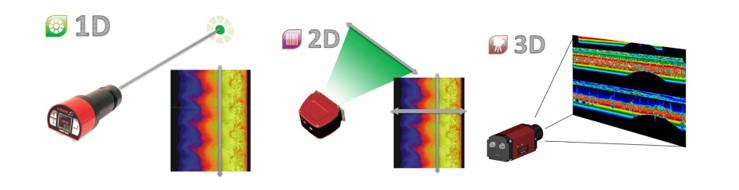

February 2023, MARIETTA, GA ~ In applications for non-contact temperature measurement, the term "HOT-SPOT measurement" is commonly used to not only recognize and measure "hot spots" or areas of high temperature, but also detect cold, cooler areas and show their distribution. In principle, the temperature of an object in a process can be detected and measured in three ways: Using a PYROMETER which detects the object temperature at one spot. This means it is a temperature measurement at one spot over time (1D).The temperature measurement relates to a fixed point - HOT SPOT - of a non-moving object over time, e.g. in applications in which a certain area is heated, where the temperature must be determined and the process must be controlled. This results in a current temperature trend, which can be used to control the heating process. Using an (IR) LINE SCANNER This method detects the temperature along a measuring line (profile). Each scan-line consists of 1,000 individual measuring points (samples) and thus generate an exact temperature profile. With measuring frequencies of up to 150 lines per second - corresponding to 150,000 measuring points per second, fast-moving objects, e.g. in rolling processes, result in an accurate and continuous measurement of the temperature distribution. Using a THERMAL IMAGER A well-known type of "HOT-SPOT measurement" is the use of a typical portable thermal imaging camera for building thermography to find hot/cold bridges and leaks on the building. In the field of industrial thermal imaging, hot areas are detected on moved or non-moved objects, detecting the object HOT SPOTS and the whole temperature distribution.

To read more on AMETEK Land's "HOT SPOT" measurement capabilities, Click Here

|