|

PRESSURE PULSES CAN CAUSE FALSE ALARMS

TO O2 SENSORS September 2023,

MARIETTA, GA ~

Oxygen Sensors are sensitive to pressure: The output from partial pressure sensors is 100%

proportional to the ambient pressure; therefore, changes

in atmospheric pressure can produce false alarms. For

example, if the pressure increased by 15 kPa (i.e. 15%

increase at an ambient pressure of 1 atmosphere) then

the oxygen sensor output will increase by 15%: from

20.9% to 24% oxygen, causing the gas detector to

alarm.

The output from mass flow-controlled sensors (including

the most of our oxygen sensors) are not 100%

proportional to the ambient pressure, showing a much

reduced pressure effect: about 7% dependent; for

example, a 15 kPa pressure change (i.e. 15% pressure

increase) will cause the sensor output to increase by

7% of 15%: a 1.05% output increase from 20.9 to 21.1%

oxygen, avoiding an alarm. However, mass flow oxygen

sensors show transient behavior when subjected to a

rapid change in ambient pressure.

Rapid pressure changes can occur in several situations:

• If a portable safety instrument is

placed in the trunk of the car and the

lid is closed then the instrument will

see a temporary positive pressure

change.

• If a miner descends rapidly into a

deep mine, the gas detector will see

a rapid positive pressure pulse.

• If a technician or operator passes

through an airlock then the gas

detector will respond to a positive or negative

pressure pulse.

• Hand aspirated or pumped samplers cause positive or

negative pressure pulses.

Although mass flow controlled oxygen sensors show

transient behavior due to pressure pulses, good design

and validation of the pressure pulse effect can minimize

this problem.

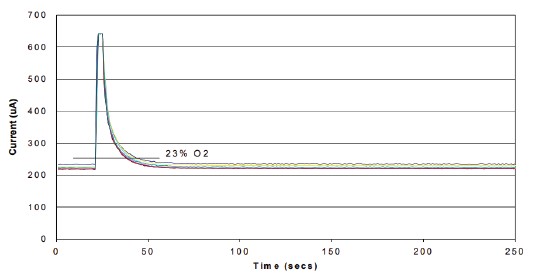

Positive and Negative Pressures: A positive change in pressure leads to an almost instantaneous

increase in the output from the oxygen sensor, decaying in

a shape reminiscent of discharge of a capacitor. Negative

pulses also show the same characteristic but are much smaller

in magnitude and most alarms occur from positive pressure

pulses. Characteristics of a Positive Pressure Pulse: A positive pressure pulse can be characterized by two

parameters:

• Pulse peak height

• Time spent above 23% oxygen, which is a typical alarm level;

this parameter assists designers in defining permissible time

windows for ignoring pressure pulses. This time is specified for

near-instantaneous pressure changes, but some applications

create a ramped pressure step, such as a descent into a coal

mine.

• Time spent above 23% oxygen, which is a typical alarm level;

this parameter assists designers in defining permissible time

windows for ignoring pressure pulses. This time is specified for

near-instantaneous pressure changes, but some applications

create a ramped pressure step, such as a descent into a coal

mine. Oxygen Sensors

and Transient Pressure Behavior:

These characteristics listed

below can help customers to design the system to minimize alarms due to pressure

changes.

1. Peak height is linearly

dependent on the magnitude of the pressure change, for pressure pulses or steps

up to 2 bar. Above 2 bar, peak height sensitivity is reduced.

2. Pressure changes less than

2kPa can be ignored.

3. The time in alarm (i.e., a

reading greater than 23% oxygen) increases linearly with the magnitude of the

pressure change.

4. Positive pressure changes

cause peaks that have a peak height typically three times greater than troughs

from negative pressure changes.

5. You should quantify the

magnitude and rate of pressure changes for your applications in order to

determine alarm time windows and expected peak heights.

6. Pressure changes are

usually very fast (except for descents into mines) - much faster than any

expected change in oxygen concentration. This allows software intervention to

determine whether a sensor output transient is due to a true oxygen change or a

pressure change.

7. Sensors with higher output

are less sensitive to pressure changes: the O2-A1 has the smallest peak height

and the O2-A3 has the largest peak height.

To learn more

about the RC Systems

click here

|